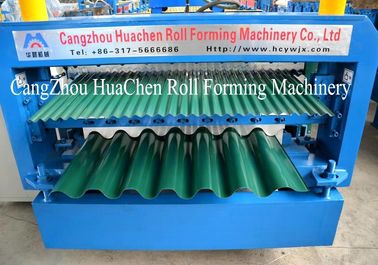

Horizontal Speed 15-18m / min Cold Roll Former , Corrugated roofing sheet making machine

Application:

Double Layer Roll Forming Machine can separate produce corrugated roof and IBR roof in one line or similar two profiles.

The products are widely used in building the steel-structure large-scale warehouse, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and different kinds of greenhouses.

Technical Parameters:

1) Main motor power: 5.5kw

2) Drive: Chain

3) Main shaft dia: ¢76mm material: 45# forge steel and quenched

4) Roller material: 45# forge steel and quench treatment hardness 58-62, chrome coated 0.05mm

5) Roll station: 16 groups for upper layer and 20 groups for lower layer

6) Raw material: 0.3-0.8mm

7) Width of raw material: 1250mm

8) Valid width after fromed: 1150mm&1000mm9) Working speed: 10m--15m/min(Exclude cutting time)

10) Length Tolerance: ±2mm

11) Weight of machine: about 8ton

12) Size of machine: About 10500×1800×1900mm L x W x H

13) Color of machine: depend on customer14) Coder: Omron

15) Control: PLC Panasonic, made in Japan. 380V 50HZ

16) Computer operating panel: touching screen

17) Cutting: Hydraulic cutting18) Auto cutting when reach the set length.

19) Hydraulic power: 3KW

20) Blade material: Cr12,quenched 58°-62°

21) Working pressure:16mpa

22) Cutting tolerance: +/- 1.5mm

Working flow:

Uncoiler—Feeding—roll forming--- hydraulic cut to length—output table

Character of main structure

a) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

b) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

d) It is very easy to install the equipment and suitable for producing in the factory.

e) Low noise with high efficiency

Advantage:

available for two profiles roof panel shared one frame, save the cost.

1) Used to produce different roof panels and wall panels

2) Produced panels have such advantages as below:

a) Fine profile

b) Attractive color

c) Agile connecting

d) Slightly curved

3) dual-level roll forming machine

4) We can design and manufacture different type of it to hit your particular profiles

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!